This article features Packaging Solutions Specialist Miranda Jeffress.

As consumers become more aware of the environmental impact of the products they purchase, companies are under pressure to make their packaging more sustainable. But what does that mean, and how can it be achieved? This blog post will explore six tips for packaging your products more sustainably.

1. Use Sustainable Materials

“It used to be that you made a choice on packaging based on price, delivery, and quality. But that is not all anymore,” says Miranda Jeffress, a Packaging Solutions Specialist at New-Tech. “Sustainability is now a huge factor when making a choice in packaging.”

Due to the growing environmental interest, the options for sustainable packaging have grown.

Many types of packaging, such as corrugated boxes and void fill, can now be made using recycled paper and plastics. Packaging materials made from biodegradable plant-based substances, such as corn starch or cellulose, will break down over time and not add to the amount of waste in landfills.

2. Rightsize Your Package

When it comes to packaging products sustainably, one of the most important things companies can do is to rightsize their packages to reduce waste. That means using the smallest possible package to protect the product and allow it to function properly.

Every year, billions of pounds of packaging material end up in landfills or incinerators. By using less material, we can help reduce this environmental impact.

Rightsizing also saves money, Jeffress points out. The less material used in packaging, the lower the production costs and potentially lower freight/shipping costs.

“When the box is too big, that means there is waste,” Jeffress says. “Switching to a recyclable packaging mailer, for example, could make a huge impact. You can cut material and shipping costs while sending out a package that is easy for the consumer to recycle. Ultimately, it's good for the environment, the consumer, and your bottom line.”

3. Reduce Waste Inside the Package

Using less packaging material inside the package is another way to pack more sustainably. This starts by rightsizing your package, so you don’t need to overpack.

Also, look for void fill that is recyclable or compostable, and be sure all is correctly labeled, so consumers know how to recycle or compost it.

Making your packaging more sustainable doesn’t have to be complicated – often, small changes can make a big difference to help reduce waste and conserve resources without compromising quality.

4. Cut Down on Damages

Damaged products are a cost to the environment – period. The replacement of the product contributes to landfill waste, additional packaging materials, manufacturing resources, carbon emissions, and more. A single damaged product adds up quickly!

An evaluation, such as New-Tech’s Collaborative Packaging Evaluation, can help determine where packaging improvements can be made to reduce damages.

“At New-Tech, we also test and do trial runs to ensure the packaging properly protects the product as needed before it heads out the dock,” Jeffress says.

5. Consider Returnable Packaging

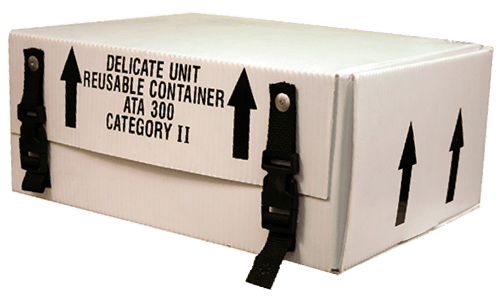

Returnable packaging, such as reusable suitcases and corrugated plastic packaging, is an environmentally-friendly way to transport or store products while protecting products from drops, vibrations, scratches, harsh weather, changing temperatures, and more. It can be used multiple times, reducing material costs and waste.

One challenge of using reusable packaging is that it often requires a higher initial investment than single-use packaging. However, the long-term savings from using reusable packaging can be significant.

6. Use a Supplier that Cares about Sustainability

Most importantly, find a supplier that understands your objectives and goals regarding packaging and sustainability.

At New-Tech, we offer a variety of eco-friendly packaging solutions, from lightweight recyclable materials to packaging automation that reduces waste.

We advise our customers to start with our Collaborative Packaging Evaluation, where our team of packaging experts will come to your facility to evaluate the packaging processes, design, materials, waste, etc., and then provide you with detailed recommendations and bottom-line ROI. Contact us today to request your free evaluation.