Efficiency, consistency, and cost-effectiveness are extremely important in the fast-paced world of manufacturing and distribution. As businesses strive to meet consumer demands while maintaining quality standards, the role of automation in packaging operations becomes increasingly indispensable. End-of-line packaging automation offers a ton of benefits that not only streamline processes but also elevate overall performance and profitability. Keep reading to see how New-Tech Packaging can help increase productivity with automated packaging equipment.

Benefits of End-of-line Packaging Automation

Enhanced Efficiency

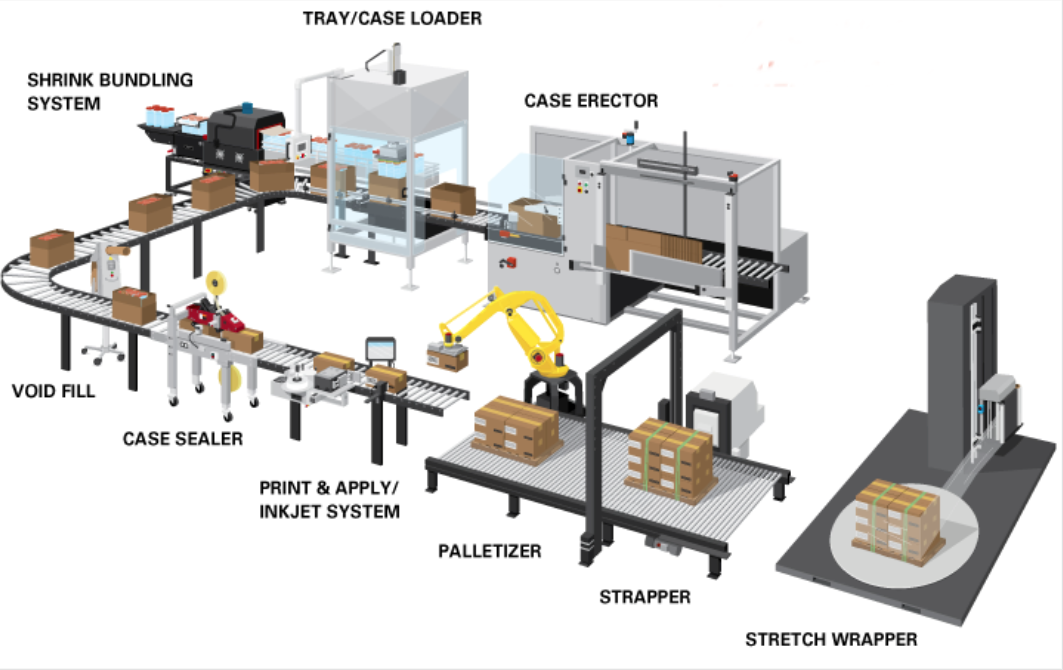

One of the most significant advantages of end-of-line packaging automation is its ability to streamline operations, reducing time-consuming manual tasks. By automating repetitive processes such as case erecting, sealing, labeling, and palletizing, businesses can significantly boost efficiency and productivity. Tasks that once required hours of labor can now be completed in a fraction of the time, allowing employees to focus on more value-added activities.

Cost Savings

In addition to enhancing efficiency, automated packaging systems lead to long-term cost savings. By reducing the need for manual labor, businesses can lower labor costs while minimizing waste. Moreover, optimized resource utilization and decreased downtime contribute to overall cost efficiency, making automation a smart investment for businesses looking to improve their bottom line.

Consistent Results

Automation ensures that every package is handled with precision and uniformity, minimizing errors and maintaining a high standard of quality. Whether it's labeling, sealing, or palletizing, automated systems deliver consistent results, eliminating variations caused by human error. This consistency not only enhances the customer experience but also strengthens brand reputation by ensuring product integrity and reliability.

Increased Throughput

With the rapid processing capabilities of automated systems, businesses can accommodate higher production demands without a proportional increase in labor. End-of-line automation enables seamless scalability, allowing businesses to ramp up production without compromising quality or efficiency. This increased throughput not only meets growing market demands but also enhances overall competitiveness in the industry.

Customized Solutions

End-of-line packaging automation offers flexibility, with solutions tailored to suit various product types, sizes, and packaging materials. Whether you're handling fragile items, irregular shapes, or bulk quantities, automated systems can be customized to meet your specific requirements. This adaptability not only improves operational efficiency but also enhances product presentation and customer satisfaction.

Quality Assurance

Incorporating quality control checks into automated processes guarantees that each package meets the required standards and specifications. From weight verification to barcode scanning, automated systems ensure that products are packaged accurately and securely. By minimizing the risk of defects and inconsistencies, businesses can uphold quality standards and minimize costly recalls or returns.

Safety Improvement

Automation minimizes the risk of workplace injuries associated with manual packaging tasks, creating a safer working environment for employees. By eliminating repetitive motions, heavy lifting, and exposure to hazardous materials, automated systems reduce the likelihood of accidents and injuries. This prioritization of safety not only protects employees but also fosters a positive work culture and boosts employee morale.

Optimized Space

End-of-line automated systems can be designed to occupy less floor space, optimizing facility layout and resource allocation. Whether it's a compact case erector or a space-saving palletizing system, automation enables businesses to make the most of available space without compromising functionality. This efficient use of space not only improves workflow but also reduces overhead costs associated with facility expansion or relocation.

Data Insights

Automation enables data collection and reporting, providing valuable insights into packaging processes for continuous improvement. By tracking key metrics such as throughput, downtime, and error rates, businesses can identify inefficiencies and implement targeted improvements. This data-driven approach not only enhances operational efficiency but also facilitates informed decision-making and strategic planning.

Scalability

One of the most compelling advantages of end-of-line automation is its scalability. As businesses grow and production volumes increase, automated packaging solutions can easily be scaled to accommodate changing needs. Whether it's adding additional modules or upgrading existing systems, automation offers flexibility and agility, ensuring that businesses can adapt to evolving market demands and maintain a competitive edge.

Choose New-Tech for All of Your Packaging Needs

End-of-line packaging automation offers a multitude of benefits that can revolutionize your packaging operations. From enhanced efficiency and cost savings to improved quality assurance and safety, automation provides a strategic advantage in today's competitive marketplace. By investing in automated systems, businesses can optimize their processes, elevate their performance, and achieve long-term success.

If you're interested in exploring end-of-line packaging automation solutions for your business, New-Tech Packaging offers a wide range of innovative and customizable solutions to meet your needs. Contact us today to learn more about how automation can transform your packaging operations and drive business growth!