We’re used to seeing packaging material made from corrugated paper or cardboard. Fasten your seatbelts, though, because that’s changing fast. Corrugated plastic has been taking the packaging industry by storm.

Why Are Plastic Corrugated Packages So Popular?

They are popular because:

• They’re stronger: They offer better support for your products and won’t just crumple with a slight impact.

• It’s possible to reuse them several times: The packaging industry has come under fire for overusing plastic. Using plastic smartly, though, means a solution that you can use over and over again. That’s far better than one-use paper or cardboard products.

• They’re water-resistant: In ideal circumstances, this wouldn’t be an issue. But we can’t always transport our goods in perfect conditions.

What Sorts of Plastic Corrugated Boxes Can You Make?

If you can envision it, we’ll probably be able to create it. Corrugated plastic is a highly versatile material to work with. Let’s go over some of the more common types.

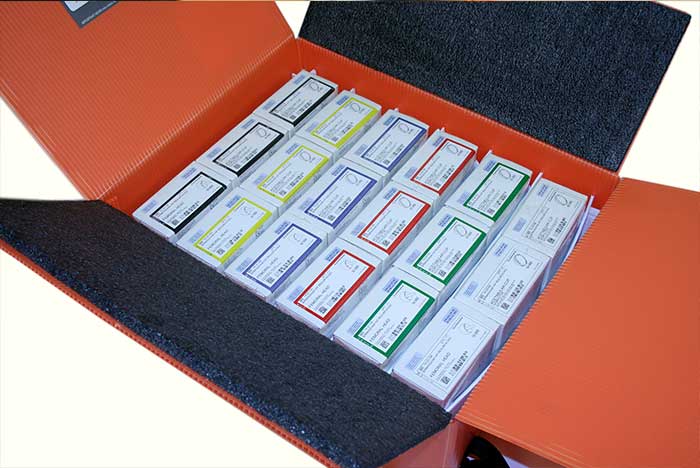

Die-Cut Shippers and Hand Totes

Hand totes can be custom made to your specifications. They usually require stacking frames, as well. You can select a design that exactly fits the part you’re shipping. The inside of the tote is often foam, plastic, or a mix of both. Die-cut shippers are cut using a custom die. The container is typically shipped flattened. Erecting the box is simple thanks to the score lines impressed into it. When the client has finished with them, they can break them down and ship them back flat. We’ll custom make these to your specifications. Give us a call if you want advice on designing the perfect packing container.

Get Ready for Long-Term Savings

These products require more of an upfront investment. If, however, you’re in a position to reuse the containers, this investment will pay for itself after five trips. Before opting for this solution, it’s essential to work out if it’s practical for clients to return the containers.

If your clients are unlikely to return the containers, it’s not worth investing in them. There are several incentives that you can offer to encourage them to do so, though. So, speak to us, and we’ll discuss your options with you.

There are other factors to consider here. Say, for example, that you’re in an industry where high humidity or moisture is a factor. The convenience food industry is one such example. These boxes will stand up moisture and steam a lot better than their paper counterparts.

Finally, these containers are recyclable. Once their useful lifespan is over, they can be sent off to the recyclers with a clean conscience.

Would You Like to Find Out How Much Money You’ll Save?

Give us a call at (901) 466-8770 or click on this link. Let our team conduct our unique 12 Point Packaging audit to see if this is the right solution for your business.